Rea u amohela CHUANGRONG

18 Years Factory Dn20-200 Fully Automatic Electrofusion Welding Machine

"Botšepehi, Boqapi, Bokhabane, le Ts'ebetso" ehlile ke mohopolo o phehellang oa mokhatlo oa rona ho fihlela nako e telele ho theha mmoho le bareki bakeng sa poelano le phaello e kopaneng bakeng sa lilemo tse 18 fektheri ea Dn20-200 Fully Automatic Electrofusion Welding Machine, Ho ba re le k'hamphani ea rona e ntseng e tsoela pele ho leka, empa re sa atlehe ho ba k'hamphani ea rona. molekane ya makatsang.

"Botšepehi, Boqapi, Bokhabane, le Ts'ebetso" ehlile ke mohopolo o phehellang oa mokhatlo oa rona ho fihlela nako e telele ho theha hammoho le bareki bakeng sa poelano le phaello e kopanetsoeng bakeng saChina Electrofusion Welding Machine le Electro Welding Machine, Re tla etsa sohle se matleng a rona ho sebelisana 'moho le ho khotsofatsoa ke uena ho itšetleha ka boleng ba boemo bo holimo le theko ea tlholisano le ho fetisisa ka mor'a ts'ebeletso, ka tieo re labalabela ho sebelisana le uena le ho etsa likatleho nakong e tlang!

Lintlha tse qaqileng

| Tšebeliso: | Khokahano ea ho Fittings Pipe ea Electrofusion | Ho fanoe ka tšebeletso ea ka mor'a thekiso: | Likarolo tsa Mahala tsa Spare, Ho kenya Tšimo, Komisi le Koetliso, Tlhokomelo ea Tšimo le Ts'ebeletso ea Tokiso, Tšehetso ea Marang-rang, Tšehetso ea Theknoloji ea Video. |

|---|---|---|---|

| Tiisetso: | Selemo se le seng | Sebaka sa ho sebetsa: | 20-1000mm, 15KW |

| Welding Output Voltage: | 8-75V | Mofuta oa Sephutheloana: | Lebokose la Lehong |

Tlhaloso ea Sehlahisoa

Mochini oa Welder oa 630mm O Sebelisa Bakeng sa HDPE Plastic Pipe Jointing Heater

* MCU ea boemo bo holimo e sebelisoa e le setsi sa taolo, se nang le li-parameter tse ngata, litekanyo le ts'ebetso e phethahetseng ea ts'ireletso;

* Pontšo e phahameng ea kristale ea mokelikeli, e tšehetsa lipuo tse ngata, ts'ebetso ea konopo ea ho ama, sebopeho sa mochini oa motho;

* Phatlalatso e pharalletseng ea motlakase le motlakase, tse loketseng boemo ba marang-rang a motlakase sebakeng seo;

* Taolo e nepahetseng e phahameng ho matla le nako ea motlakase, netefatsa boleng ba welding;

* Nako ea karabo e potlakileng ha phepelo ea motlakase e robeha, botsitso bo phahameng;

* Tšehetsa rekoto ea ho bala ea disk ea U;

* Tšehetsa paramethara ea foromo ea ho kenya disk ea U;

* Tšehetsa printa e nkehang ea USB, rekoto ea ho tjheseletsa ea khatiso;

* E na le ts'ebetso ea phala ea boitsebahatso ka boits'oaro;

*Mosebetsi o motle oa tšireletso habeli;

* Ka mekhahlelo e ka bang 6, e ka ikamahanya le litlhoko tse fapaneng tsa ho cheselletsa liphaephe;

*Tsehetsa mefuta e fapaneng ea li-parameter tsa welding: ho kenya letsoho ka letsoho, ho ntšoa ha foromo, ho kenyeletsoa ha barcode scanning;

* Boto ea taolo e amohela theknoloji ea welding ea SMT ho fokotsa sekhahla sa ho hloleha ha mochini kaofela.

Tekheniki Parameters

| Ho kenya motlakase | E lekantsoe matla a ho kenya | 220V±20% |

| E lekanyelitsoe khafetsa | 45-65Hz | |

| Phepelo ea motlakase e tsoang | Rated output voltage | Sheba mofuta oa tlhaloso |

| Matla a hlahisang | Sheba mofuta oa tlhaloso | |

| Litšobotsi tsa ho laola | Mokhoa oa ho laola | Motlakase o sa feleng, o lula o le teng |

| Bongata ba motlakase bo nepahetseng kamehla | ≤±0.5% | |

| Ho nepahala ha taolo ea nako | ≤±0.1% | |

| Mocheso o lekanyang ka nepo | ≤1% | |

| Scan bar code | Skena 24 bit bar code ho lumellana le ISO 13950-2007 | |

| Ambient | Mocheso oa tikoloho | -20℃50℃ |

| Mocheso oa polokelo | -30℃70℃ | |

| Mongobo | 20% ~ 90% RH, ha ho condensation | |

| Ho thothomela | <0.5G, ha ho na vibrate e mabifi le tšusumetso | |

| Bophahamo | <1000m AMSL, ha≥1000m de-rate ho latela GB/T3859.2-93 |

Tlhaloso ea mosebetsi

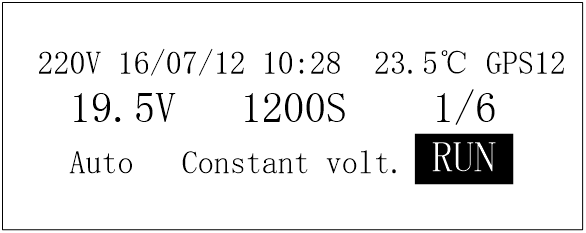

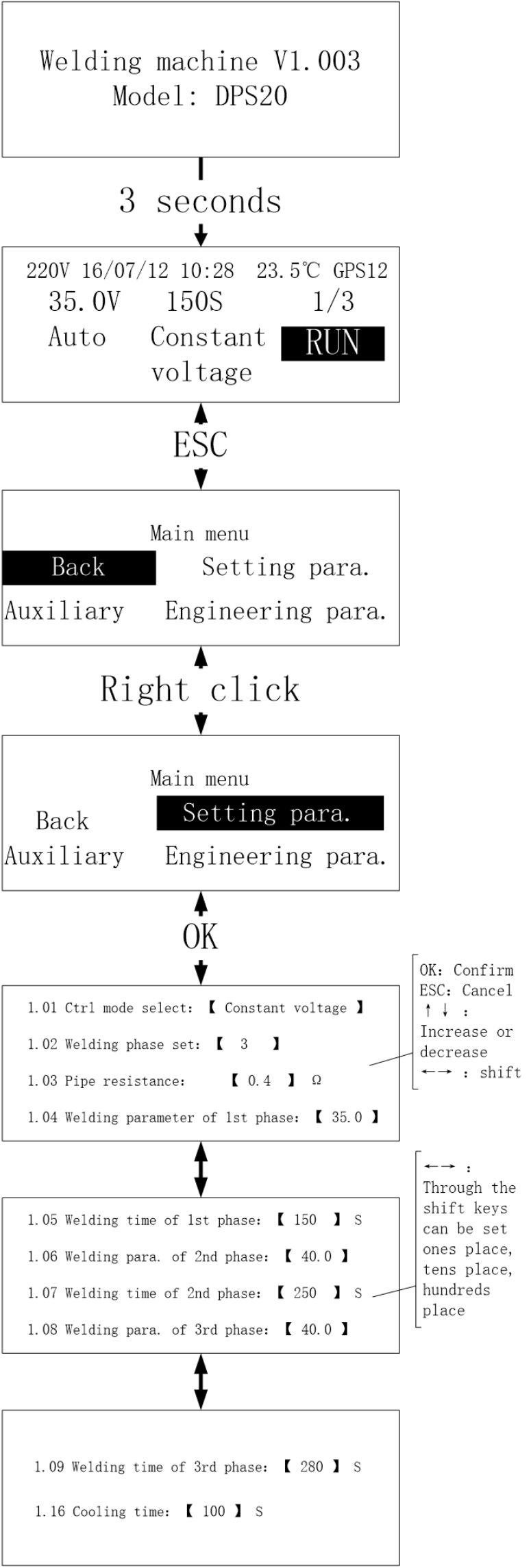

1 Single phase welding

Ka mor'a hore motlakase o khannoe, mochine oa welding o kena ka mokhoa o ikemetseng ho sebopeho sa welding joalokaha ho bontšitsoe ka tlase, tsamaisa cursor ka ho le letšehali le ka ho le letona, u tobetsa konopo ea "OK" ka mor'a hore cursor e fetele ho li-parameter tse lumellanang le eona, ebe li-parameter li le boemong bo fokolang.

Ka linotlolo tsa holimo le tlase ho fetola boleng ba parameter, tobetsa konopo ea "OK" ho boloka boleng ba data. Haeba o tobetsa konopo ea "ESC" ho lahla phetoho, data e tla khutlela boleng ba data pele e fetoloa. Ho beha boleng ba "1.03 pipe resistance" ho lekana le khanyetso e lumellanang ea pipe.

Ka mor'a hore li-parameter tsa welding li behoe, tsamaisa cursor ho "RUN" 'me u tobetse "OK" ho kenya ts'ebetso ea welding.

Tlhokomeliso: Beha "1.03 pipe resistance" ho 0 haeba u sa tsebe ho hanyetsa liphaephe, feela phoso ea potoloho e bulehileng (ho hanyetsa ha pipe e kholo ho feta 20 ohms kapa tlhahiso ea hona joale ke 0) e fumanoa nakong ea ho lemoha lipeipi. Empa tlhophiso ena e tla tima ts'ebetso ea "alamo ea boitsebahatso ba liphaephe", ka hona e ke ke ea beoa ha ho hlokahala.

2 Multiple phases welding

Haeba ts'ebetso ea phala e hloka mekhahlelo e mengata ea ho tjheseletsa, hoa hlokahala ho fetola "mekhahlelo ea ho beha" → boleng ba parameter bo lekanang le boleng ba karolo e lakatsehang ea "setting ea nomoro ea 1.02".

Ka mohlala: ho hanyetsa phala 0.4Ω, mokhoa o tsitsitseng oa motlakase, 3 welding, mohato oa pele: metsotsoana ea 35V / 150, ea bobeli: metsotsoana ea 40V / 250, ea boraro: metsotsoana ea 40V / 280, nako ea pholileng ke metsotsoana e 100.

Taba ea pele, re hloka ho fetola boleng ba "1.02 welding phase phase" ho isa ho 3, beha boleng ba "1.03 pipe resistance" ho 0.4Ω, beha boleng ba "1.04 parameters welding" ho 35V, ebe u beha boleng ba "1.05 1sttjheseletsa nako” ho metsotsoana e 150. Sena se phethela karolo ea pele ea litlhophiso tsa tjheseletsa.

Qetellong, o hloka ho beha boleng ba "1.16 pipe cooling time" ho metsotsoana e 100. 'Me joale ho hlophisoa ha li-parameter tsa welding ho phethoa. Tobetsa konopo ea "ESC" ho khutlela ho sebopeho sa welding sa standby, u ka bona boleng ba liparamente le boleng ba nako li tšoana le litlhophiso tse fetileng. Tsamaisa sesupa ho "RUN" ebe o tobetsa "OK" ho kenya ts'ebetso ea welding.

Mehato ea ts'ebetso e bontšitsoe ka tlase:

3 Ho tjheseletsa sekena

Haeba phala e khomaretsoeng le bar code joalo ka ha ho bonts'itsoe ka tlase, u ka e bala ka sekena. Lintlha tse latelang tsa barcode welding parameters ke: motlakase o sa feleng: 39.5V, nako ea welding: metsotsoana e 200, nako ea ho phomola: metsotso e 15.

Kamora hore mosebelisi a hokahane hantle, a sebelisa sekenara ho skena barcode mme sekena se tla etsa molumo o reng "beep", 'me u ka bona boleng ba liparamente tsa welding tse hlahlobiloeng ke bar code ho sehokelo sa standby sa welding.

Tlhokomeliso: 1, Ke mofuta oa mochini oa welding o nang le "S" o nang le ts'ebetso ea ts'ehetso ea ts'ebetso ea ho hlahloba;

2、Barcode e lokela ho lumellana le mofuta oa khoutu ea "barcode ea 3.06";

3, E tlameha ho sebelisa sehatisi se inehetseng se hlomelloang ke k'hamphani ea rona.

Keletso: laser le bar code ha se likhato tse 90 ka ho felletseng, phello ea ho skena e ntle ka ho fetesisa, sekhahla sa ho sekama se holimo le tlase ke ± 65 °, angle e sebetsang ea ho sekama e holimo le tlase ke ± 60 °, sekhahla se nepahetseng sa ho sekama ke ± 42 °. Ka kopo, lumella laser hore e koahele khoutu eohle ea bar, ho seng joalo u ka sitoa ho bala lintlha tse nepahetseng.

Kopo

Sehlahisoa ke sesebelisoa se hokahanyang se sebelisetsoang khatello ea polythene le electrofusion ea phala e sa hatelleheng kapa khokahano ea soket.

"Botšepehi, Boqapi, Bokhabane, le Ts'ebetso" ehlile ke mohopolo o phehellang oa mokhatlo oa rona ho fihlela nako e telele ho theha mmoho le bareki bakeng sa poelano le phaello e kopaneng bakeng sa lilemo tse 18 fektheri ea Dn20-200 Fully Automatic Electrofusion Welding Machine, Ho ba re le k'hamphani ea rona e ntseng e tsoela pele ho leka, empa re sa atlehe ho ba k'hamphani ea rona. molekane ya makatsang.

"Botšepehi, Boqapi, Bokhabane, le Ts'ebetso" ehlile ke mohopolo o phehellang oa mokhatlo oa rona ho fihlela nako e telele ho theha mmoho le bareki bakeng sa poelano le phaello e kopaneng bakeng sa lilemo tse 18 fektheri ea Dn20-200 Fully Automatic Electrofusion Welding Machine, Ho ba re le k'hamphani ea rona e ntseng e tsoela pele ho leka, empa re sa atlehe ho ba k'hamphani ea rona. molekane ya makatsang.

18 Lilemo FektheriChina Electrofusion Welding Machine le Electro Welding Machine, Re tla etsa sohle se matleng a rona ho sebelisana 'moho le ho khotsofatsoa ke uena ho itšetleha ka boleng ba boemo bo holimo le theko ea tlholisano le ho fetisisa ka mor'a ts'ebeletso, ka tieo re labalabela ho sebelisana le uena le ho etsa likatleho nakong e tlang!

Re romelle molaetsa oa hau:

Lihlopha tsa lihlahisoa

-

Mohala

-

E-mail

-

Whatsapp

-

Skype

-

Holimo

Re romelle molaetsa oa hau:

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur