Rea u amohela CHUANGRONG

High Pressure Steel Plastic composite SRTP Pipe Steel Wire e Matlafalitsoeng HDPE Pipe e Kopantsoeng

Litaba tsa Motheo

CHUANGRONG e lula e fana ka lihlahisoa tse ntle ka ho fetisisa le theko ho bareki. E fa bareki phaello e ntle ho nts'etsapele khoebo ea bona ka kholiseho e kholo. Haeba u thahasella k'hamphani le lihlahisoa tsa rona, ka kopo u se ke oa tsilatsila ho ikopanya le rona bakeng sa lintlha tse ling.

High Pressure Steel Plastic composite SRTP Pipe Steel Wire e Matlafalitsoeng HDPE Pipe e Kopantsoeng

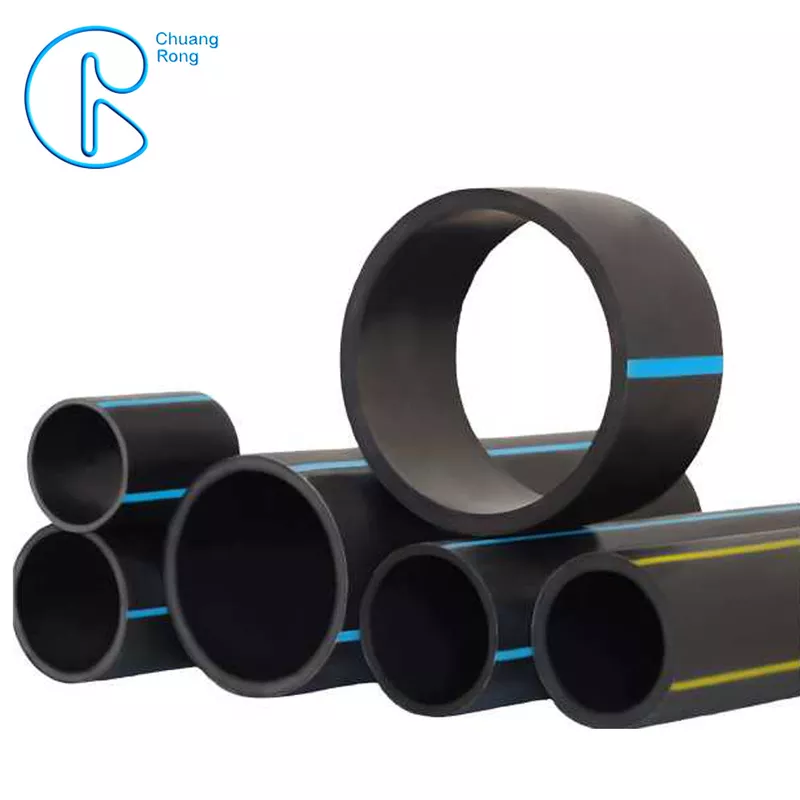

| Lebitso la Sehlahiswa: | Peipi e entsoeng ka tšepe ea polasetiki ea tšepe ea tšepe ea tšepe ea tšepe e matlafalitsoeng ka HDPE | Kopo: | Lipalangoang tsa Mafura a Khase, Ho nosetsa le phepelo ea metsi |

|---|---|---|---|

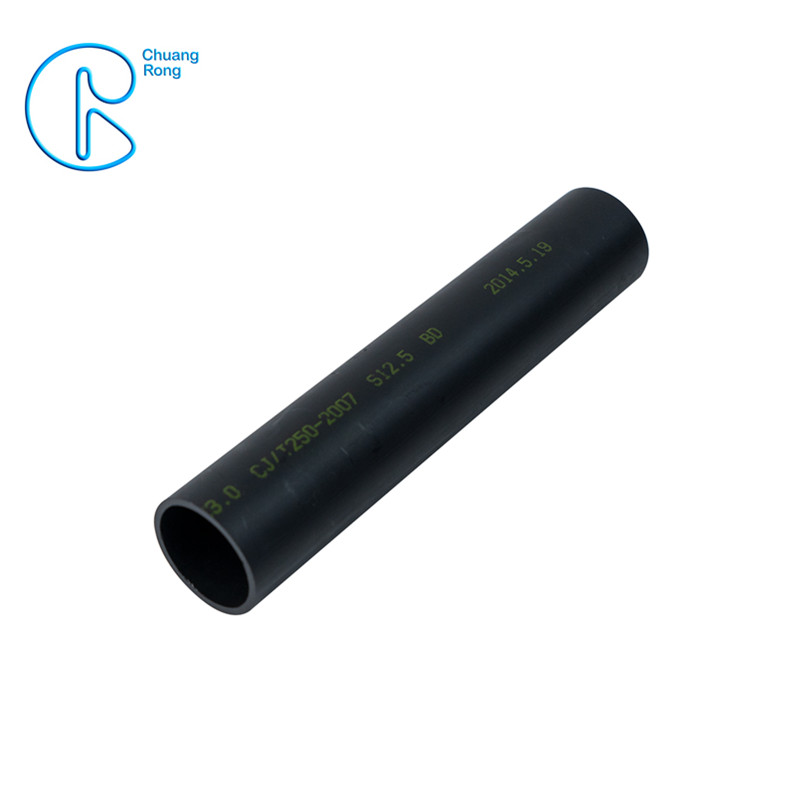

| Boitsebiso: | 100% Virgin Material PE100 le terata ea tšepe | Tloaelo: | CJ/T189-2007 , GB/T32439-2015 |

| Tlhaloso: | DN50-1000 limilimithara | Setifikeiti sa Boleng: | WRAS,CE,ISO,BV,SGS,Tlaleho ea Teko ea Feme jj |

Rea u amohela ho etela feme ea rona kapa ho etsa tlhahlobo ea mokha oa boraro.

Rea u amohela ho ikopanya le rona bakeng sa lintlha tsa lihlahisoa le tšebeletso ea litsebi.

Ka kopo, romella lengolo-tsoibila ho:chuangrong@cdchuangrong.com

Tlhaloso

High Pressure Steel Plastic composite SRTP Pipe Steel Wire e Matlafalitsoeng HDPE Pipe e Kopantsoeng

| Khatello | 0.8Mpa | 1.0Mpa | 1.25Mpa | 1.6Mpa | 2.0Mpa | 2.5Mpa | 3.0Mpa | 3.5mpa | 4.0Mpa | 5.0Mpa | 6.3Mpa | 7.0Mpa |

| Tlhaloso(mm) | Botenya ba Lebota(mm) | |||||||||||

| 50 | 4.5 | 5.0 | 5.5 | 5.5 | 5.5 | 6.0 | 8.5 | 9.0 | 9.5 | |||

| 63 | 4.5 | 5.0 | 5.5 | 5.5 | 5.5 | 6.5 | 8.5 | 9.0 | 10.0 | |||

| 75 | 5.0 | 5.0 | 5.5 | 6.0 | 6.0 | 9.5 | 9.5 | 9.5 | 10.5 | |||

| 90 | 5.5 | 5.5 | 5.5 | 6.0 | 6.0 | 10.0 | 10.5 | 10.5 | 11.5 | |||

| 110 | 5.5 | 5.5 | 7.0 | 7.0 | 7.5 | 8.5 | 8.5 | 11.0 | 12.0 | 12.0 | 12.0 | |

| 125 | 5.5 | 5.5 | 7.5 | 8.0 | 8.5 | 9.5 | 9.5 | 11.0 | 12.0 | 12.0 | 12.0 | |

| 140 | 5.5 | 5.5 | 8.0 | 8.5 | 9.0 | 9.5 | 9.5 | 11.0 | 12.0 | 13.0 | 13.0 | |

| 160 | 6.0 | 6.0 | 9.0 | 9.5 | 10.0 | 10.5 | 10.5 | 11.0 | 12.0 | 14.0 | 14.0 | |

| 200 | 6.0 | 6.0 | 9.5 | 10.5 | 11.0 | 12.0 | 12.5 | 13.0 | 13.0 | 15.0 | 15.0 | |

| 225 | 8.0 | 8.0 | 10.0 | 10.5 | 11.0 | 12.0 | 13.0 | 13.0 | 13.0 | |||

| 250 | 8.0 | 10.5 | 10.5 | 12.0 | 12.0 | 12.5 | 14.0 | 14.0 | 14.0 | 15.0 | ||

| 280 | 9.5 | 11.0 | 11.0 | 13.0 | 13.0 | 15.0 | 15.0 | 17.0 | ||||

| 315 | 9.5 | 11.5 | 11.5 | 13.0 | 13.0 | 15.0 | 15.0 | 18.0 | ||||

| 355 | 10.0 | 12.0 | 12.0 | 14.0 | 14.0 | 17.0 | 17.0 | 19.0 | ||||

| 400 | 10.5 | 12.5 | 12.5 | 15.0 | 15.0 | 17.0 | 17.0 | |||||

| 450 | 11.5 | 13.5 | 13.5 | 16.0 | 16.0 | 18.0 | ||||||

| 500 | 12.5 | 15.5 | 15.5 | 18.0 | 18.0 | 22.0 | ||||||

| 560 | 17.0 | 20.0 | 20.0 | 22.0 | 22.0 | |||||||

| 630 | 20.0 | 23.0 | 23.0 | 26.0 | 26.0 | |||||||

| 710 | 23.0 | 26.0 | 28.0 | 30.0 | ||||||||

| 800 | 27.0 | 30.0 | 32.0 | 34.0 | ||||||||

| 900 | 29.0 | 33.5 | 35.0 | 38.0 | ||||||||

| 1000 | 34.0 | 37.0 | 40.0 | |||||||||

Tlhaloso ea Sehlahisoa

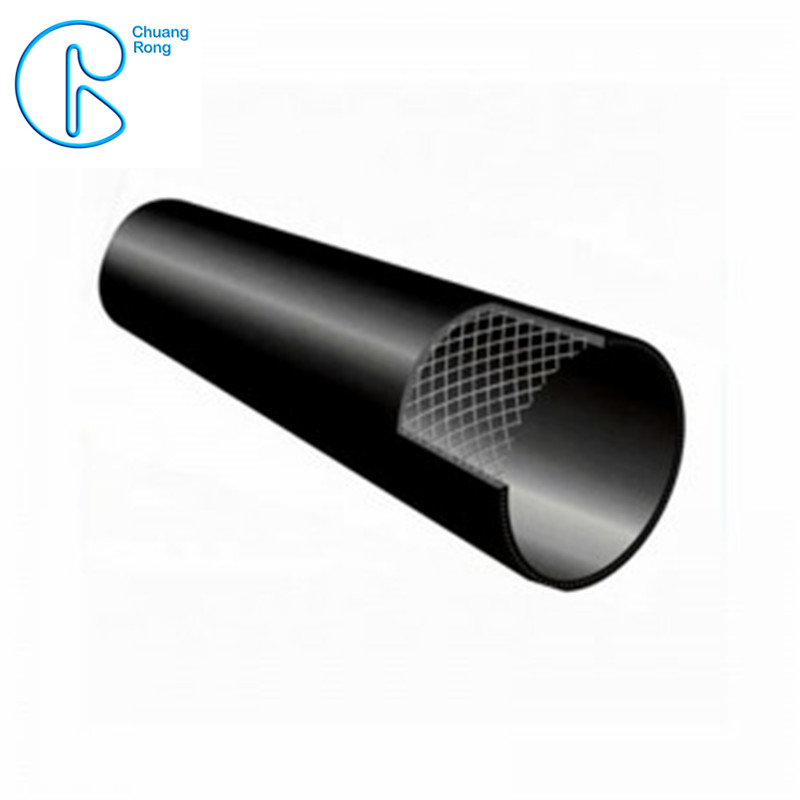

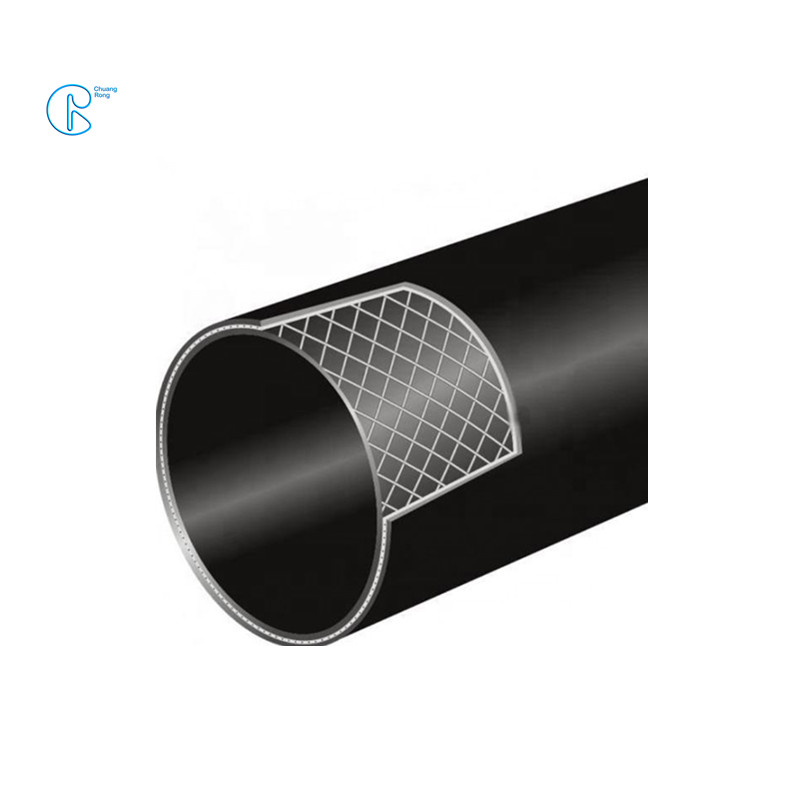

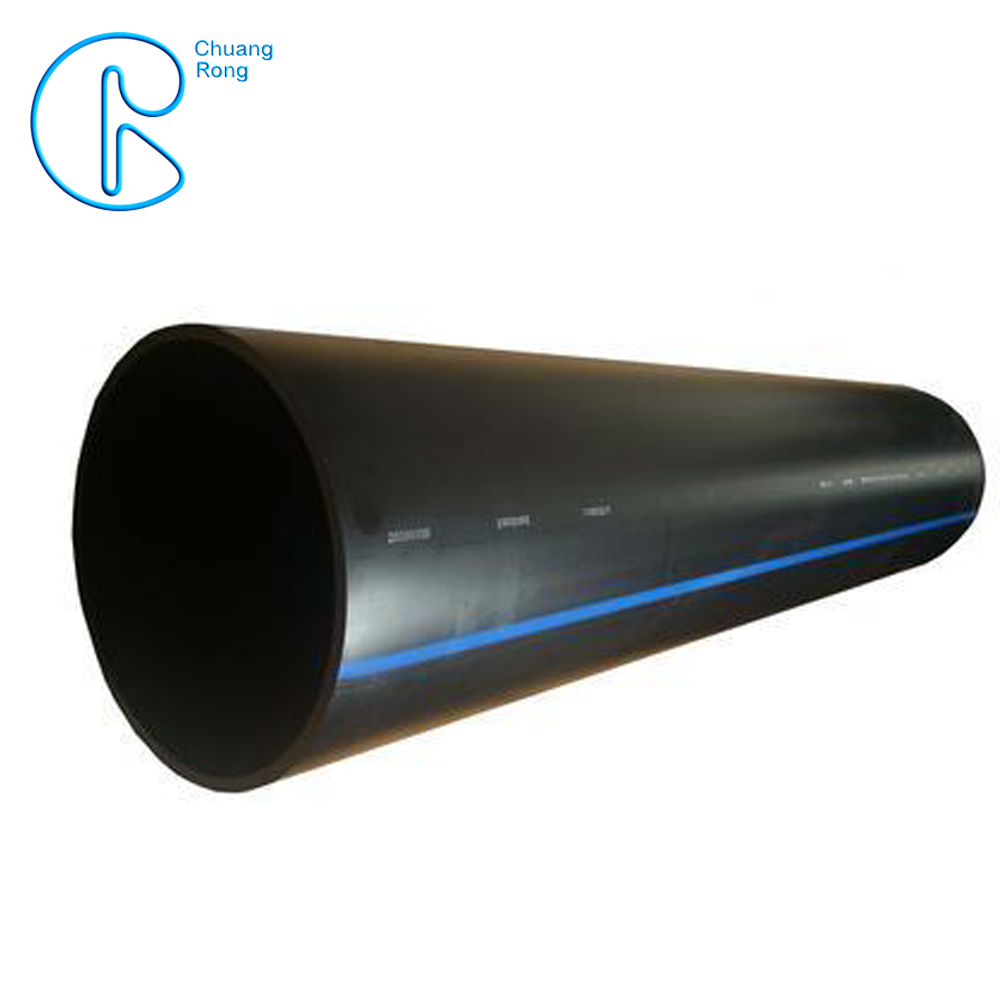

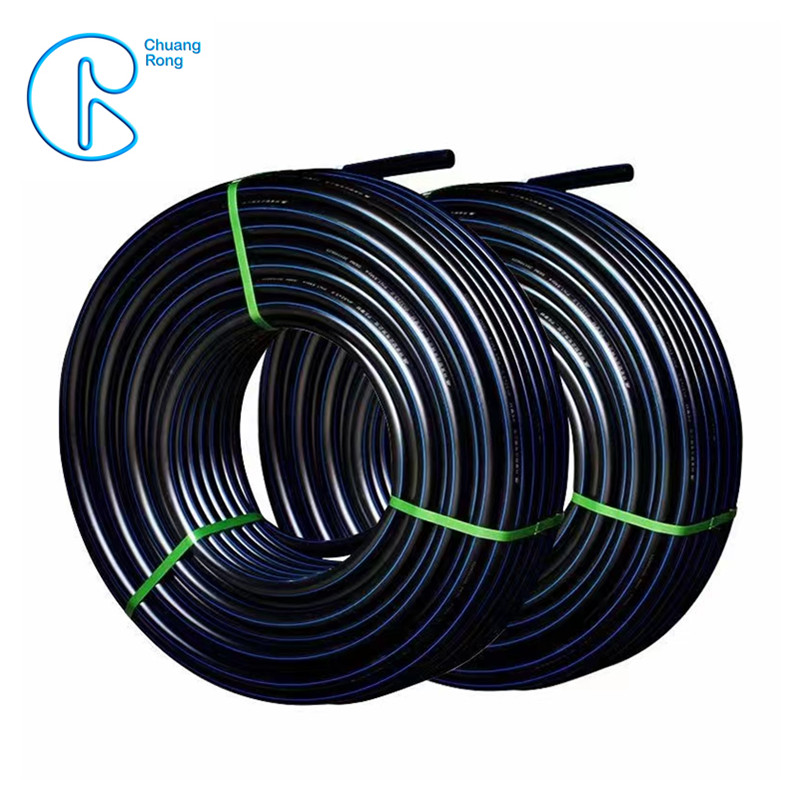

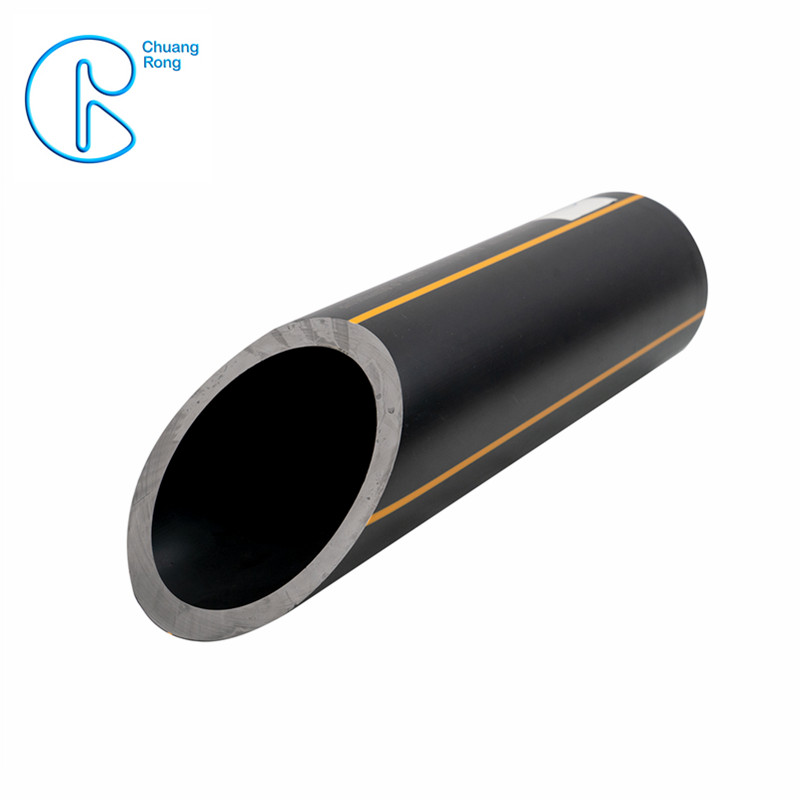

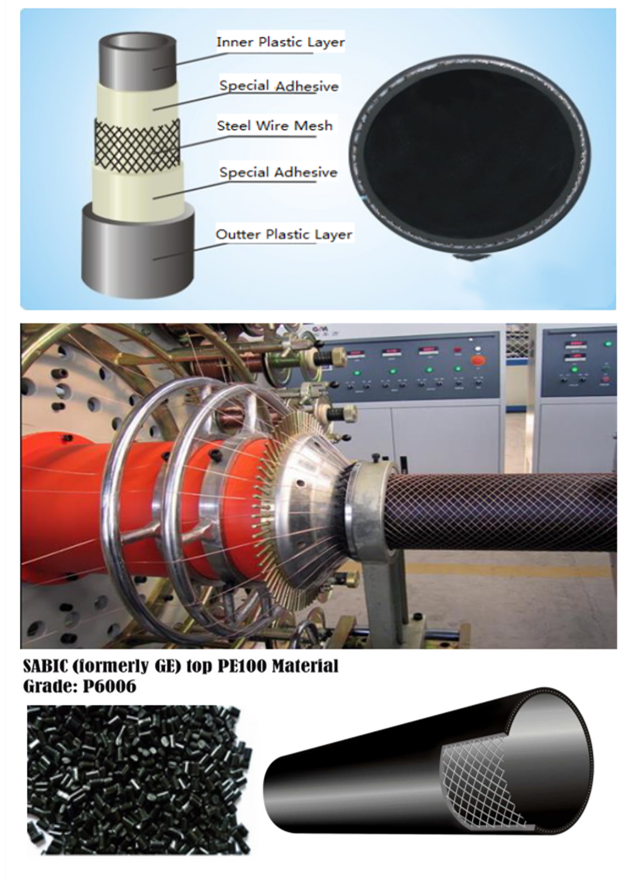

Mesh ea tšepe e matlafalitsoeng HDPE Pipe e kopantsoeng e kopantsoe le lera le khethehileng la sekhomaretsi se chesang ho polasetiki.Bokaholimo ba phala bo na le likarolo tse ts'oanang tsa ho hanyetsa kutu le ho roala ho hanyetsa.Lerako le ka hare le boreleli bakeng sa lipalangoang ntle le scaling, ha ho boka, ho hanyetsa kutu le ho boloka matla.Pipe ena e na le chelete e ngata ebile e loketse bakeng sa lipalangoang tse ka tlas'a lefatše le maemo a ka tlas'a lefatše a senyehang, ho senyeha ha tikoloho ho ka senyeha. litšisinyehong tsa lefatše. Ka lebaka la matla a matla a terata ea tšepe, e na le bokhoni bo ikhethang ba ho ikamahanya le maemo a tlase le maemo a mang. Ho ipapisitsoe le melemo e kaholimo, peipi ea mofuta ona e khethoa e le phala ea metsi e patiloeng ka tlas'a lefatše ea lebala la lipapali la naha nakong ea kaho ea libaka tsa Liolimpiki.

Likaroloana

1.Matla a phahameng, ho tiea le ho hanyetsa tšusumetso ha ho bapisoa le lipeipi tse tiileng tsa PE.

2. Ho hanyetsa ha kutu ka mahlakoreng a mabeli, ho tšoana le ts'ebetso ea ho hanyetsa ha kutu ea phala ea polasetiki.

3. Ho eketsa boemo ba kopo ea mocheso ka lebaka la mocheso o tlaase oa conductivity coefficient.Ha ho hlokahale tšireletso ea mocheso ea lebota le ka ntle mariha, 'me ha ho na condensation ea mongobo lehlabula.

4. Lerako le ka hare le boreleli, ha le na sekhahla, le fokotsa 30% tahlehelo ea hlooho ea metsi ha e bapisoa le pipe ea tšepe.

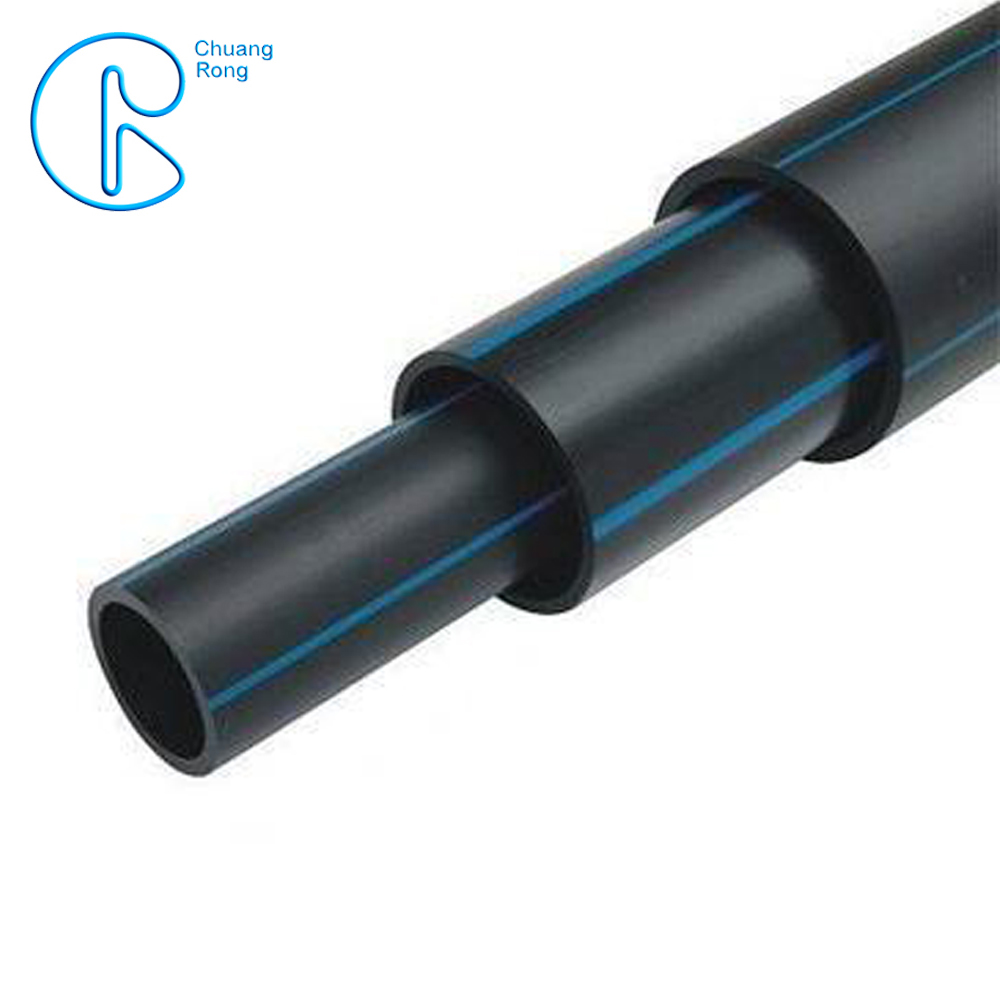

5 Lipeipi li hokahane ka tsela ea electrofusion, e natefeloang ke theknoloji e butsoitseng, khokahano e bonolo le e sireletsehileng, ts'ebetso e matla ea axial tensile, le litlhaloso tse fapaneng tsa ho kenya liphaephe.

6. Boima bo bobebe, lipalangoang tse bonolo le kaho, le ts'epahalo e phahameng ka kakaretso ea liphaephe. Tlas'a maemo a tloaelehileng, bophelo ba ts'ebeletso bo ka fihla lilemo tse 50.

7.Ke eona sebaka se setle ka ho fetisisa sa liphaephe tse entsoeng ka masenke ka lebaka la theko e tlase le bohloeki.

8.Sebopeho se entsoe ka ho sotha terata ea tšepe ea spiral, eo ka bobeli e ka natefeloang ke litlhaku tse tlase tsa katoloso ea mela e tlase le ho feto-fetoha ha maemo hantle ntlheng ea axial, kahoo e ntlafatsa ts'ebetso ea tikoloho.

9. E ka ba e loketseng hantle bakeng sa masimo a kopo ea lipalangoang tsa metsi a malelele tlas'a maemo a thata a ho sebetsa.

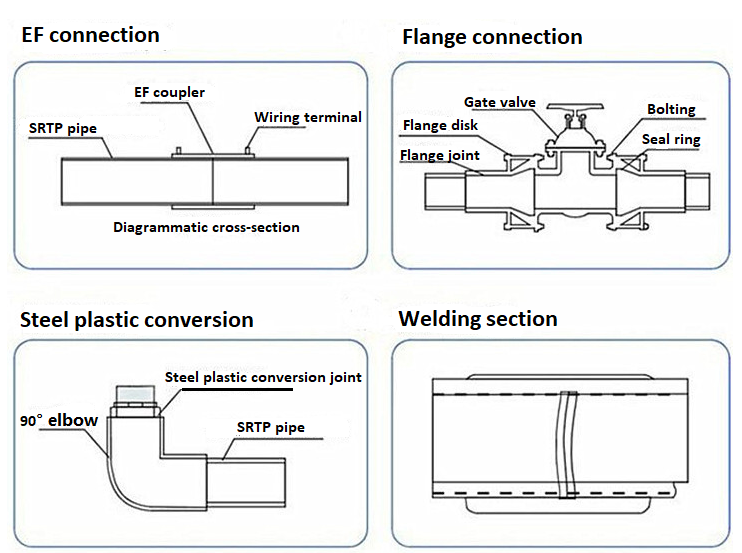

Mekhoa ea Khokahano

Elektro Fusion Joint

Mokhoa ona oa ho kopanya mocheso o batla o fapane le motsoako o tloaelehileng oa ho kopanya.Phapang e kholo pakeng tsa motsoako o tloaelehileng oa mocheso le motlakase ke mokhoa oo mocheso o sebelisoang ka oona. Ka mokhoa o tloaelehileng oa ho kopanya mocheso, sesebelisoa sa ho futhumatsa se sebelisetsoa ho futhumatsa phala le libaka tse loketseng.Lenonyeletso la motsoako oa electro fusion le futhumatsoa ka hare, ebang ke ka mohala oa terata ka har'a sebopeho sa motsoako kapa, joalo ka moralo o le mong, ka polymer.Heat e bōptjoa ha motlakase o sebelisoa ho lisebelisoa tsa conductive ka mokhoa o loketseng. Mehato e akaretsang e lokelang ho lateloa ha o kopanya electro fusion ke:

1.Lokisetsa liphaephe

2. Tlanya li-fittings le liphaephe

3.Sebelisa motlakase oa motlakase

4.Ho bata 'me u tlose li-clamps

Kopo

Mesh ea tšepe e matlafalitsoeng ke pipe ea HDPE Composite ke mofuta o mocha oa lipeipi tse sebetsang hantle haholo, tse sebelisoang haholo masimong a oli, lifemeng tsa motlakase, lik'hamphani tsa lik'hemik'hale le tsa petrochemical, lik'hamphani tsa metsi, khase ea masepala, lipeipi tsa metsi a leoatle le masimo a mang.

CHUANGRONG e na le sehlopha se hloahloa sa basebetsi se nang le boiphihlelo bo bongata. Sehlooho sa eona ke Integrity, Professional and Efficient. E thehile likamano tsa khoebo le linaha le libaka tse fetang 80 indastering e amanang. Tse kang United States, Chile, Guyana, United Arab Emirates, Saudi Arabia, Indonesia, Malaysia, Bangladesh, Mongolia, Russia, Afrika joalo-joalo.

Rea u amohela ho ikopanya le rona bakeng sa lintlha tsa lihlahisoa le tšebeletso ea litsebi.

Ka kopo, romella lengolo-tsoibila ho:chuangrong@cdchuangrong.com kapa Mohala:+ 86-28-84319855

Re romelle molaetsa oa hau:

Lihlopha tsa lihlahisoa

-

Mohala

-

E-mail

-

Whatsapp

-

Skype

-

Holimo